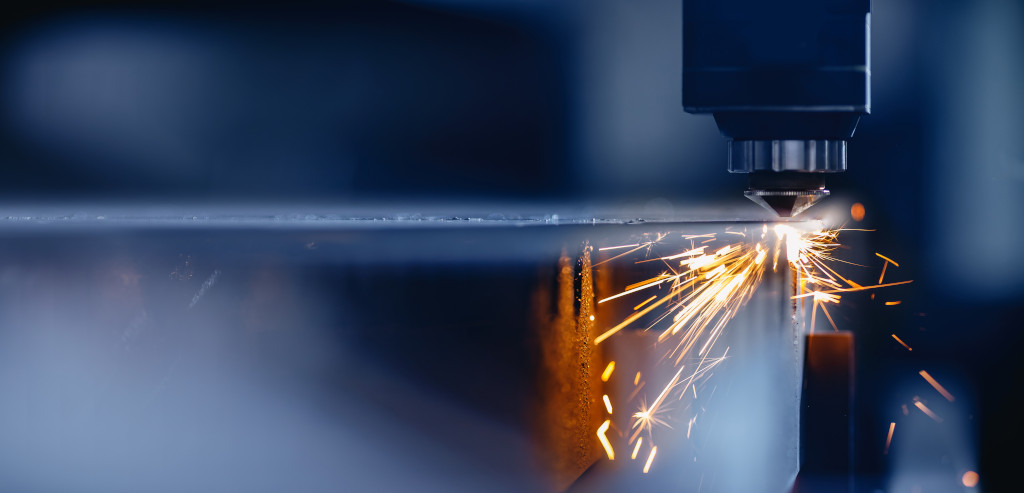

Transforming Metal Fabrication: How Metal Laser Cutting Services Revolutionize Industries

These days, metal laser cutting is a widespread service, thanks to recent advances in technology and programming, and the fabrication technique’s accuracy, efficiency, precision, and speed. Laser cutting has brought many changes to the fabrication industry, revolutionizing every industry that relied on the fabrication of sheet metal.

Laser cutting technology uses a laser beam, focused by an optical path system, to perform a clean, neat cut into sheets of metal. Guided by computer programming, the laser can cut a variety of intricate designs and geometries that previously had not been possible, with high precision and repeatability. It consistently results in quality, clean cuts with far less waste of material and less stress in the workpiece as well. Since the mechanical part of the laser never comes into contact with the metal, less mechanical stress is introduced to the part, and surface damage such as scratches are eliminated entirely.

Laser cutting has many other advantages as well. It’s an incredibly versatile technology, able to accommodate many different materials at varying thicknesses, depending on the equipment being used. Since the laser exerts no cutting force, it can fabricate a range of materials and complexities that are difficult to obtain through other methods, and it does so very efficiently and quickly.

This type of fabrication also tends to be more cost-effective for manufacturers and their customers alike. The equipment being used does not generate tool wear like other fabrication techniques often do, reducing both tooling and production costs. Thanks to the use of CAD/CAM technology, many different parts can be carefully and efficiently nested into one workpiece, resulting in a high reduction of material waste and costs as well.

Where laser cutting shines is in its ability to consistently produce quality, precise components with high accuracy. The quality of the process, because laser cutting is so repeatable, is far easier to maintain. Computer controls nearly eliminate human error and improve batch reliability even in medium to large production volumes. This improved quality saves lead times, reduces part errors, and can save manufacturing customers time and money in the long run.

Looking for a supplier of metal laser cutting services?

Since 2003, Decron has been a trusted partner in metal fabrication, creating quality products for our customers and working with them from start to finish to ensure they receive a high quality product on time and within budget. Check out our website to learn more.