The Top Metal Forming Techniques and When They Are Used

Metal forming is a subset of fabrication where metal is reshaped while it’s still in a solid shape. Certain metals have high plasticity, making them easier to fabricate without having to melt them or ruining the integrity of the finished products. Metal forming techniques are separated into hot-working and cold working, depending on the temperature at which the process is performed. The type of forming used and the temperature at which it is done depends heavily on the type of metal being formed.

Hot Working

Hot working techniques form metal at temperatures just above its recrystallization temperature, redistributing stresses and making the metal more ductile and easier to form. These types of techniques are used when large amounts of deformation are needed, but the metal also needs to keep its ductility.

Cold Working

Cold working refers to any forming process done at around room temperature. Cold working provides stronger products, with closer tolerances and better surface finishes. However it can affect a metal’s grain flow, which is useful in some applications, and large amounts of deformation cannot be achieved as easily.

The Most Common Metal Forming Techniques

Nearly any metal forming process can be performed at hot or (relatively) cold temperatures, and the choice of which depends on the features, strength, and type of metal required by the project. From there, metal forming can be further split into two different groups: bulk metal forming and sheet metal forming.

Bulk Metal Forming

Bulk metal forming processes metal stock shapes that have a low ratio of surface area to volume like bars or tubes. The more common types used today are rolling and casting. Rolling involves feeding metal stock through a set of rollers that reform it into the desired shape, with little scrap, repeatable tolerances, and high strength. Casting is the process of pouring molten metal into a die or a mold in order to achieve complicated geometries.

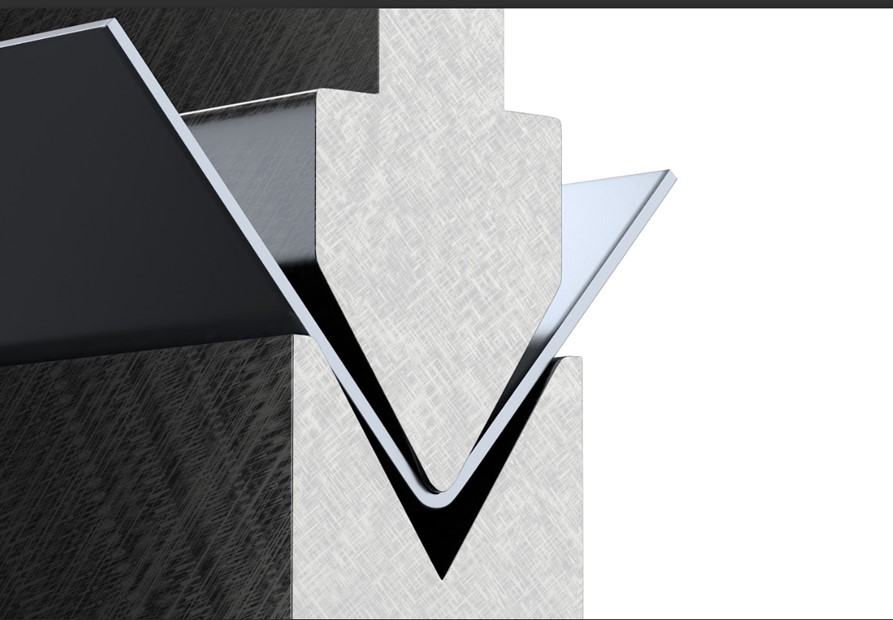

Sheet Metal Forming

Sheet metal forming, which processes metal in sheeting or plates in order to form finished products. This includes a wide range of different techniques, such as punching, bending, embossing, and stamping, all of which are good processes for consistency and production efficiency.

Looking for a supplier of metal forming services?

Decron has a wide range of equipment to cover a variety of different metal forming techniques, including bending, punching, and cutting. We work with many different metals, like steel, aluminum, stainless steel, and copper, and we provide our customers with the products that they need. For more information, check out our website today!